Pigment Red 214-Corimax Red BN

Product parameter list

| Color Index No. | Pigment Red 214 |

| Product name | Corimax Red BN |

| Product category | Organic Pigment |

| Light Fastness(coating) | 7 |

| Heat Resistance(coating) | 200 |

| Light Fastness(plastic) | 7-8 |

| Heat Resistance(plastic) | 280 |

Color |  |

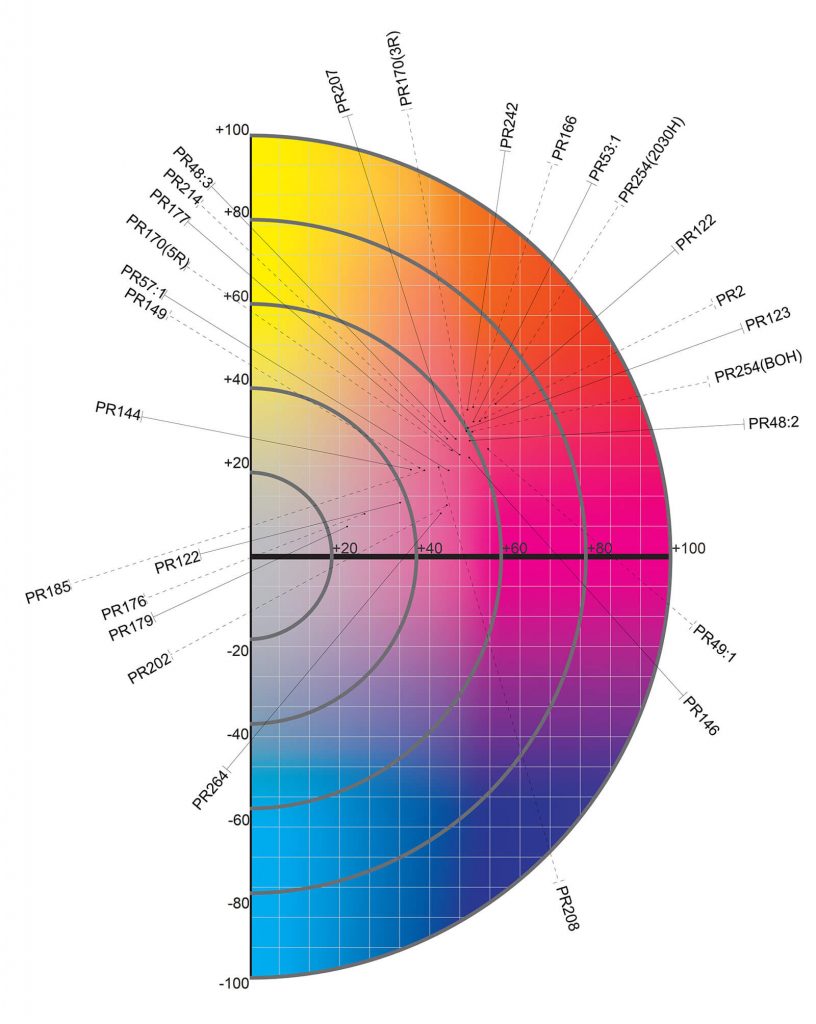

| Hue distribution |

Application:

Recommended for automotive paints, industrial paints, powder coatings, printing pastes, PVC, rubber, PS, PP, PE, PU, water based inks, solvent inks, UV inks

Suggested for architectural coatings, coil coatings, offset inks.

Pigment Red 214 gives a neutral to blue light red, and is excellent in light and gloss finishes. The pigment has high color strength in plastics, and its color light is similar to CI Pigment Red 144, but the dimensional deformation phenomenon is obvious; the heat resistance in HDPE is 300 ° C (1 / 3-1 / 25SD); it is also suitable for polypropylene pulp coloring It is resistant to migration in soft PVC. It is recommended for coloring of polystyrene and engineering plastics. It is also used for high-end printing inks, such as packaging printing inks, PVC films and metal decorative printing inks. Good resistance to acid / alkali and soap. Thermal stability 200 ° C.

Molecular formula: C40H22Cl6N6O4

Molecular weight: 863.38

CAS No: 4068-31-3

Synthetic principle: 2,5-dichloroaniline is used as the diazo component, and sodium nitrite aqueous solution is added to the hydrochloric acid medium to carry out the diazotization reaction; the diazonium salt is reacted with 2-hydroxy-3-naphthoic acid to form The monoazo dye is reacted with sulfoxide in an organic solvent to be converted into an acid chloride derivative; and then subjected to a condensation reaction with 2,5-dichloro-1,4-phenylenediamine to produce a crude azo-condensed red pigment , And then subjected to pigmentation treatment to obtain CI Pigment Red 214.